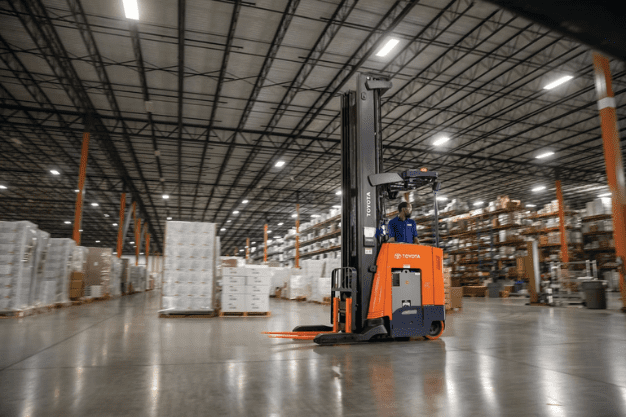

You are in charge of a warehouse, with items all over the place, forklifts moving quickly, and lanes crammed with stock. It always feels a bit claustrophobic, even though you know you have to be efficient. What if there was a method to improve speed, make room, and lighten everyone’s workload? The stand-up forklift comes next.

When you think about warehouse optimization, these little devices might not be the first thing that springs to mind, but believe me, they are quite powerful. They are made for one purpose: to complete tasks in confined locations more quickly and safely.

Thus, let’s break it down and see how these stand-up forklifts are revolutionizing the warehouse industry and facilitating lean operations.

What is Lean Warehousing Operations?

Let’s keep things easy. Reducing waste and increasing efficiency are the main goals of lean warehouse operations. It’s similar to cutting off the extra meat off a steak so you can get to the meat.

This entails cutting down on pointless motions, optimizing workflows, and ensuring that everything moves seamlessly from one area to another in a warehouse. It involves minimizing downtime, making efficient use of resources, and arranging your workspace so that everything has a place and can get to its destination quickly.

“Okay, great, lean’s all about processes—but what does equipment have to do with it?” is probably what you’re thinking right now. The proper equipment is like the engine of a well-functioning automobile in a warehouse.

You’re just coasting along without it. You’re racing to the finish line with it.

Benefits of Stand-Up Forklifts for Lean Operations

Space Efficiency

Let’s talk about space. It’s often the most underutilized resource in a warehouse, right? With a standing forklift, those narrow aisles that usually seem like a hassle can be turned into super-efficient spaces.

You get better use of every square foot. Think of it like moving around a packed room full of furniture. Now, imagine you have a smaller, more agile way of moving through all that clutter.

That’s what these forklifts do—they allow you to maximize your storage capacity without sacrificing speed.

Enhanced Maneuverability

Have you ever felt like you were doing a clumsy dance with a machine when attempting to turn around a large forklift in a narrow aisle? Everybody has been there.

However, the stand-up forklift makes navigating tight places, turning corners, and entering and exiting areas effortless. Better control results from the operator’s improved perspective position when they stand.

They can see past obstructions, maneuver through aisles with ease, and cut down on the amount of time it takes to move from one place to another.

Speed & Accessibility

Speed is key in any warehouse, right? And the faster you can get your forklift operators to the goods they need, the quicker you can move items in and out.

With standing forklifts, access is almost immediate. Operators can jump in, grab what they need, and get to the next task.

Less time fiddling with seating adjustments, less time in traffic, and more time moving goods. Simple as that. Faster workers, faster turnover, and more orders filled.

Improving Warehouse Safety with Stand-Up Forklifts

Let’s confront it, safety is a major concern. You are aware of how quickly things may go wrong if you have ever been in a noisy warehouse. The stand-up forklift excels in this situation.

Increased Visibility

Giving the operator a greater perspective of the warehouse is one of the forklift’s finest features. Because there are fewer blind zones when standing, operations are safer.

No more trying to peek around a corner or guess where the forklift is in relation to the shelf. The clear, elevated view helps operators navigate without bumping into things—or people. And speaking of safety, better visibility means fewer accidents. It’s as simple as that.

Reduced Risk of Accidents

When the operator has a clearer view, there’s less chance of accidents, right? Stand-up forklifts reduce blind spots, which means fewer crashes into pallets, shelving units, or even coworkers.

This alone can save a ton of time and money, not to mention reducing the stress on everyone working on the floor.

Ergonomics and Comfort

Long shifts? No problem. The standing position of these forklifts reduces the strain that comes with sitting for hours. You’d be surprised how much of a difference it makes to your back and legs.

This helps keep operators comfortable and focused, which directly impacts how efficiently and safely they work.

Stand-Up Forklifts vs. Traditional Counterbalance Forklifts

Okay, let’s get down to brass tacks. You know the benefits of standing forklifts, but you might be wondering, how they stack up against traditional models. Let’s break it down:

| Feature | Stand-Up Forklifts | Traditional Counterbalance Forklift |

| Maneuverability | Zooms through tight aisles. | Needs more space for turning. |

| Space Efficiency | Makes the most of narrow spaces. | Requires wider aisles. |

| Speed | Faster entry and exit, reducing downtime. | Slower adjustments and movements. |

| Operator Comfort | Ergonomic standing design. | Seated, but can be less comfortable over long shifts. |

| Visibility | Clearer sightlines, less risk of accidents. | Limited visibility from a seated position. |

How Stand-Up Forklifts Help Streamline Workflow and Reduce Waste

In a lean warehouse, efficiency is crucial, and standing forklifts are essential to achieving this goal. Here’s how:

Flow of Goods

By facilitating the seamless movement of products from one location to another, stand-up forklifts aid in the removal of those barriers.

- They increase operational speed and decrease delays by optimizing the flow.

- There is less waste when the process is more efficient.

Productivity gains in the warehouse are closely correlated with waste reduction.

Just-in-Time Inventory

The goal of just-in-time (JIT) inventory systems is to cut down on surplus inventory. The success of JIT depends on the efficient flow of commodities.

Stand-up forklifts are ideal for JIT because:

- They enable operators to swiftly transport goods.

- They guarantee that merchandise is put in the appropriate spot at the appropriate moment.

This effective mobility lessens inventory problems and keeps JIT systems operating efficiently.

Conclusion

Hope! This blog finds you well. As we have come to the end of this blog we all now are well aware that in this ever-changing world, it’s all about finding smarter ways to do things. And stand-up forklifts are a key tool in lean warehouse operations, focusing on offering more space and quicker workflows.

But how do you get a reliable forklift that should do all the heavy lifting for you? That’s where we, PRG Equipments come into play. We are the truster forklift dealer in the town.

We have served many customers who were looking for a reliable fork truck rental near me, ensuring an effective and efficient flow of work. So, whether you’re optimizing for speed, safety, or space, we have got you covered.

FAQ’s

1. Why are forklifts important in warehouses?

Ans: Forklifts are crucial in warehouses because they make it easier to move big objects, save time, and boost output in tight spaces.

2. What is a stand-up forklift?

Ans: Stand-up forklifts are designed for drivers to stand while working in order to increase vision and maneuverability in confined locations.

3. What is the most common forklift used in a warehouse?

Ans: The most common forklift in warehouses is the counterbalance forklift, which can lift and move large items in tight spaces.

4. What is the role of a forklift operator in a warehouse?

Ans: Forklift operators are accountable for the safe and effective loading, unloading, and moving of goods within the warehouse.

5. What are the safety rules for forklifts in a warehouse? Ans: Safety laws include things like wearing seat belts at all times, maintaining a clear view when driving, following speed limits, and ensuring that the load is balanced and secure.